Anatomy of Precision: Inside the PDK's 6DoF Main System Components

- chrish960

- Aug 11, 2025

- 4 min read

Updated: Aug 12, 2025

When you experience the ARK Portal Development Kit's lightning-fast 1.4ms response and levitation-like motion, you're witnessing the result of eight carefully engineered subsystems working in perfect harmony. Each component has been designed, tested, and optimized to deliver professional-grade performance in a compact package.

Let's take a deep dive into the engineering that makes the PDK possible.

Foundation Layer: Base Subassembly

Every precision machine needs a rock-solid foundation, and the PDK's Base Subassembly delivers exactly that. This isn't just a platform—it's an engineered foundation designed to handle the extreme forces generated by 30kW peak power and 3G accelerations.

Key Components:

6x Base Mounts: Precision-machined connection points that secure the rotary actuators

Structural Framework: Engineered to distribute loads evenly across the mounting surface

Vibration Isolation: Built-in dampening prevents external vibrations from affecting system performance

The base's symmetric design ensures that all forces are distributed evenly, whether you're mounting to a concrete floor or using the optional extension feet for portable operation.

Power and Precision: Rotary Actuator System

At the heart of the PDK's performance lies the Rotary Actuator System—six incredibly precise motors that transform electrical signals into physical motion with unprecedented speed and accuracy.

The Motor Arsenal: 6x BLDC Servomotors

These aren't ordinary motors. Each 132mm BLDC servomotor has been specifically modified from high-performance hoverboard motors, optimized for:

Direct-drive operation with no gear reduction

High-torque, low-latency response

56V operation with Kv 13.5 rating

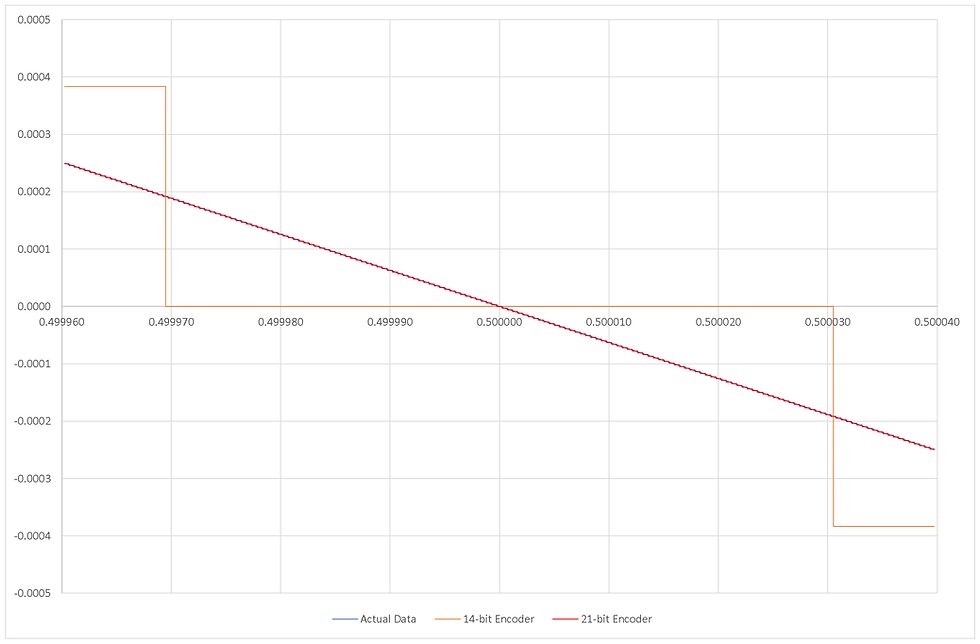

21-bit magnetic encoders providing 0.00017° resolution

Reinforced shafts and connecting rods designed for continuous high-stress operation

Intelligent Control: 3x Dual-Channel BLDC Motor Controllers (BMC)

Each motor controller manages two servomotors using advanced Field-Oriented Control (FOC) for maximum efficiency:

56V, 90A per channel rating handles peak power demands

Integrated PID control loops provide real-time position feedback

SPI encoder communication ensures ultra-low latency data transmission

CANbus system communication enables coordinated multi-motor control

Game-Changing Innovation: Weight Compensation System

The PDK's most revolutionary subsystem solves the fundamental challenge of direct-drive motion platforms: how to deliver lightning-fast response while supporting heavy payloads.

Pneumatic Powerhouse: 3x Pneumatic Cylinders

50mm bore, 140mm stroke cylinders with integrated auxiliary dead volume tanks provide:

Automatic load balancing up to 250kg payload capacity

7.0 bar maximum operating pressure for consistent force delivery

14× pressure stabilization improvement thanks to dual dead volume tanks

Passive operation during motion—no interference with servomotor control

Precision Control: Pneumatic Control Valve Block (VB)

The Pneumatic Control Valve Block continuously monitors platform load and automatically adjusts air pressure in real-time. This intelligent system:

Monitors moving mass distribution across all three cylinders

Adjusts pressure only when needed—static or dynamic operation

Maintains optimal motor torque allocation for motion rather than weight support

Air Supply: Pneumatic Air Compressor (PAC)

The integrated Pneumatic Air Compressor ensures consistent, reliable air supply:

Automatic pressure maintenance within optimal operating range

Quiet operation suitable for office and residential environments

Energy-efficient design minimizes power consumption during standby

Electrical Excellence: Power Subassembly

The PDK's impressive power delivery comes from a sophisticated Power Subassembly designed to handle both continuous operation and explosive burst demands.

Universal Power: Power Supply Unit (PSU)

3kW universal input capability provides worldwide compatibility:

Input: 100-290VAC, 47-63Hz works anywhere in the world

Output: Up to 53.5VDC optimized for BLDC motor operation

Dual power modes: 1,400W (low voltage) / 3,000W (high voltage)

Burst Power: Power Buffer Unit (Power-Bank - PB)

The Power-Bank transforms how motion platforms handle peak power demands:

3x 63V, 0.47F electrolytic capacitors with copper bus-bar interconnection

>30kW burst capability far exceeding the PSU's continuous rating

Energy recuperation stores power from deceleration phases

Instantaneous power delivery matches the burst-power nature of motion simulation

Smart Distribution: Power Distribution System

Intelligent power routing ensures every component receives clean, stable power:

Isolated power domains prevent interference between subsystems

Overcurrent protection safeguards against component damage

Thermal management maintains optimal operating temperatures

The Business End: Platform Subassembly

The Platform Subassembly is where your creativity meets our precision. The flat-top design provides:

Universal mounting surface accepts any custom superstructure

Precision-machined connection points for racing seats, flight sim cockpits, VR setups

Optimal load distribution across all six degrees of freedom

Future-proof flexibility adapts to evolving application requirements

The Brains: System Control Subsystem

Three dedicated microcontrollers work together to deliver the PDK's exceptional performance and safety.

System Management: Housekeeper Microcontroller Unit (HKP)

The ARM Cortex-M7 HKP handles system-level operations:

System monitoring and diagnostics

Safety system coordination

Power management optimization

User interface processing

Motion Magic: Motion Cueing Processor (MCP)

The ARM Cortex-M7 MCP is the performance heart of the system:

Real-time motion signal processing at up to 50,000 Hz

Inverse Kinematics calculations with our breakthrough algorithm

Trajectory generation for smooth, natural motion

Multi-format signal input support

User Control: User Interface Microcontroller (UIP)

The UIP provides essential system controls and status information:

Real-time status displays

Emergency stop functionality

Configuration management

Diagnostic reporting

Safety First: 6x Millimeter Wave Presence Sensors

mmWave presence sensors provide 360-degree environmental monitoring:

Automatic safety zone detection

Non-contact sensing prevents interference with operation

Real-time hazard assessment

Fail-safe operation modes

Connectivity Hub: Integrated Wi-Fi Router/Ethernet Switch (RTR)

The integrated networking solution ensures seamless connectivity:

100 Mbit Ethernet for high-speed wired connections

Wi-Fi capability for wireless operation and monitoring

Network isolation between control and user data

Remote monitoring support

Flexibility Options: Extension Components

Portable Power: Extension Feet (Optional)

When permanent mounting isn't possible, Extension Feet provide:

Portable professional operation

Additional weight accommodation for enhanced stability

Tool-free installation and removal

Maintains full performance in temporary setups

Ready to Race: Sim Racing Cockpit Subassembly (Optional)

The integrated racing cockpit transforms the PDK into a turnkey racing solution:

Custom-engineered chassis optimized for racing forces

Professional-grade mounting points for steering wheels, pedals, and displays

Ergonomic design for extended racing sessions

Expert motion tuning developed through years of racing simulation experience

Engineered as a System

What makes the PDK exceptional isn't just individual component quality—it's how these eight subsystems work together as an integrated whole. Every component has been designed to complement the others, creating performance that's greater than the sum of its parts.

From the precision-machined base mounts to the intelligent motion cueing processor, every element contributes to the PDK's signature combination of lightning-fast response, smooth operation, and professional reliability.

This is what happens when you don't just build a motion platform—you engineer a complete motion simulation ecosystem.

Ready to experience how these precision-engineered components work together? The ARK PDK is available now for developers, researchers, and system integrators worldwide.