The Power of Direct Drive Motors in Motion Platforms

- chrish960

- Aug 12, 2025

- 3 min read

Motion platforms like the PDK are essential in many industries, from flight simulators to robotics and virtual reality. The technology behind these platforms determines their precision, responsiveness, and overall performance. One of the most significant advancements in this field is the use of direct drive technology. This innovation has transformed how motion platforms operate, offering numerous benefits over traditional systems.

Understanding Direct Drive Technology in Motion Platforms

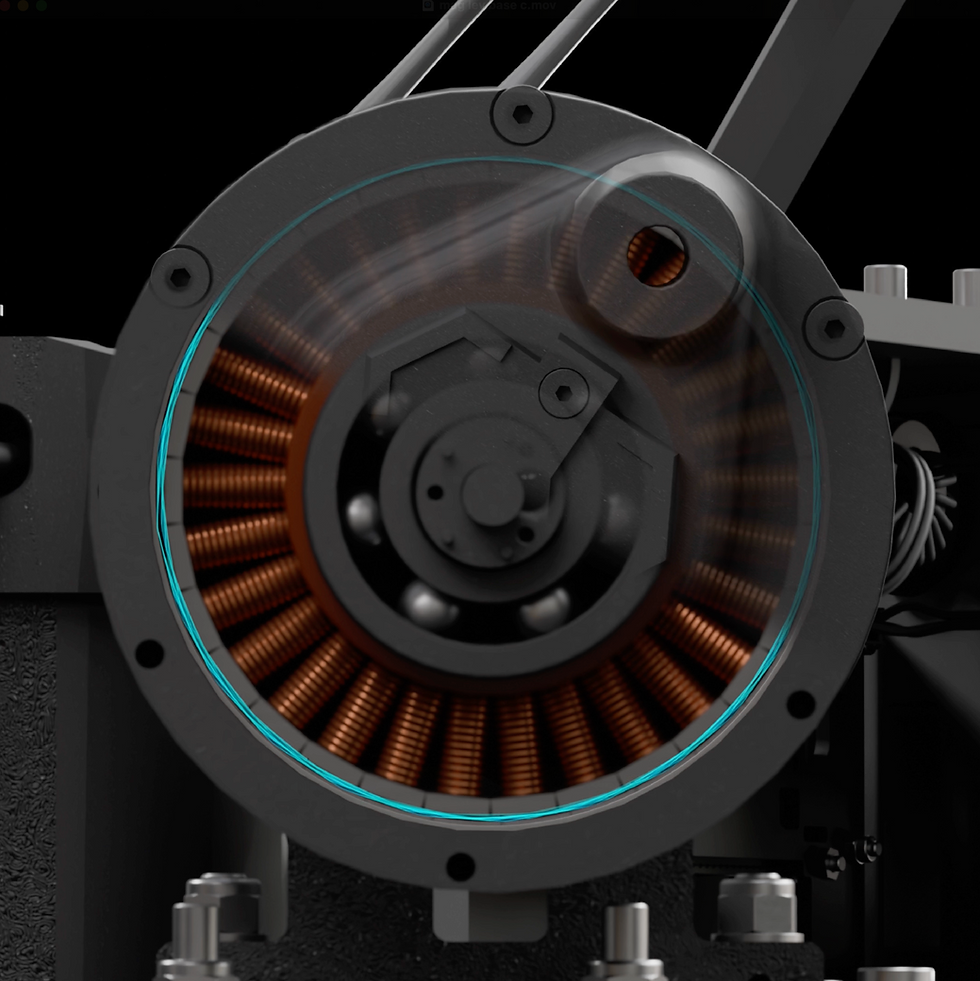

Direct drive technology eliminates the need for gears, belts, or other transmission components by connecting the motor directly to the load. This design reduces mechanical complexity and increases efficiency. In motion platforms, this means smoother, more accurate movements with less maintenance.

Traditional motion systems often rely on gearboxes or belts to transfer power from the motor to the platform. These components can introduce backlash, friction, and wear, which degrade performance over time. Direct drive technology removes these issues by providing a direct mechanical link.

Some key advantages of direct drive technology include:

Higher precision: Without intermediary parts, the platform can achieve finer control.

Reduced maintenance: Fewer moving parts mean less wear and tear.

Improved responsiveness: Direct connection allows for faster acceleration and deceleration.

Lower noise levels: The absence of gears and belts reduces operational noise.

These benefits make direct drive technology ideal for applications requiring high accuracy and reliability.

How Direct Drive Technology Enhances Motion Platform Performance

The performance improvements brought by direct drive technology are evident in several critical areas:

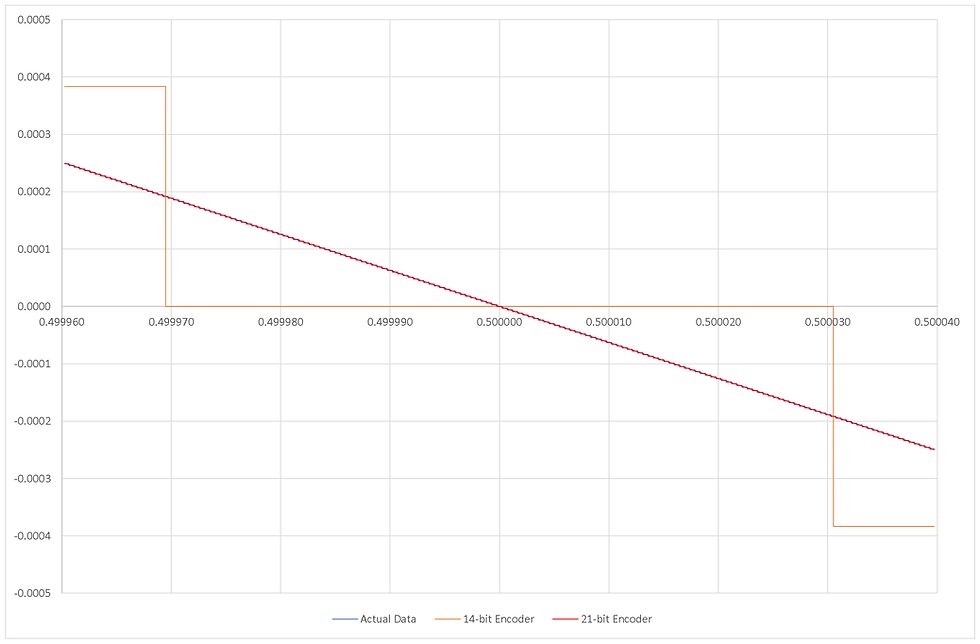

Precision and Accuracy

Direct drive motors provide exceptional positional accuracy. This is crucial in simulators where realistic motion cues are necessary for training pilots or drivers. The elimination of backlash means the platform can follow control inputs exactly, enhancing the user experience.

Smoothness and Responsiveness

Because there are no gears or belts to cause jerky movements, motion platforms with direct drive technology operate smoothly. This smoothness is vital in virtual reality setups, where any lag or vibration can cause discomfort or motion sickness.

Durability and Maintenance

Traditional systems require regular maintenance to replace worn gears or belts. Direct drive systems, with fewer mechanical parts, have longer lifespans and lower maintenance costs. This reliability is especially important in industrial applications where downtime is costly.

Energy Efficiency

Direct drive motors are more energy-efficient because they reduce power losses associated with mechanical transmissions. This efficiency can lead to lower operating costs and a smaller environmental footprint.

Compact Design

Without bulky gearboxes, motion platforms can be designed more compactly. This is beneficial in environments where space is limited or where portability is required.

Practical Applications of Direct Drive Technology in Motion Platforms

Direct drive technology is used in a variety of motion platform applications, each benefiting from its unique strengths.

Flight Simulators

Flight simulators demand high precision and smooth motion to replicate real flying conditions. Direct drive motors provide the necessary accuracy and responsiveness, improving pilot training effectiveness.

Robotics

In robotics, precise and reliable motion is critical. Direct drive technology enables robots to perform delicate tasks with high repeatability and minimal maintenance.

Virtual Reality and Gaming

Motion platforms enhance immersion in VR and gaming by providing realistic physical feedback. The smooth and quiet operation of direct drive systems improves user comfort and experience.

Industrial Automation

Manufacturing and assembly lines use motion platforms for positioning and handling tasks. Direct drive technology increases throughput by reducing downtime and maintenance needs.

Medical Devices

In medical simulators and rehabilitation equipment, precise motion control is essential. Direct drive motors help deliver accurate and repeatable movements for better patient outcomes.

Embracing the Future of Motion Platforms with Direct Drive Technology

The integration of direct drive technology in motion platforms marks a significant step forward in precision engineering. As industries demand higher performance and reliability, this technology will continue to evolve and expand its applications.

Investing in direct drive systems today can lead to improved operational efficiency, enhanced user experiences, and reduced long-term costs. Whether for simulation, automation, or entertainment, the power of direct drive technology is reshaping how motion platforms perform.