Inside the PDK: How Revolutionary Architecture Transforms 6DoF Motion Simulation

- chrish960

- Aug 9, 2025

- 4 min read

Updated: Aug 12, 2025

The ARK Portal Development Kit (PDK) isn't just another motion platform—it's a fundamental reimagining of parallel robot architecture. By combining proven Stewart platform principles with groundbreaking innovations, we've created a system that delivers unprecedented performance in a compact, practical package.

Foundation: The Stewart Platform Legacy

At its core, the PDK is a six degrees of freedom (6-DoF) parallel manipulator built on Stewart platform architecture—the gold standard for precise, multi-axis motion control. This foundation provides the mathematical elegance and mechanical precision that has made Stewart platforms the choice for high-end aerospace simulators and research applications for decades.

But we didn't stop at tradition. Every element of the PDK represents an evolution of this proven architecture.

The Nonapod Innovation: Nine Legs, Six Degrees of Freedom

Here's where ARK Dynamics breaks new ground. While traditional Stewart platforms use six actuators for six degrees of freedom, the PDK employs what we call a "nonapod" configuration—literally meaning "nine-legged" (εννεάποδο in Greek).

The Secret: Intelligent Leg Distribution

Six Servomotor Legs: These directly coupled rotary actuators provide all active positioning and movement control, maintaining the classic Stewart platform's non-redundant structure.

Three Pneumatic Legs: These additional elements operate as part of our revolutionary automatic weight compensation system, typically functioning passively during motion.

This 9-leg design gives us the best of both worlds: the precise control characteristics of a traditional 6-DOF system with the enhanced capability that comes from intelligent weight management.

Symmetric Perfection: Three-Cluster Connection Strategy

The PDK's connection architecture follows a precisely engineered axially symmetric pattern with all nine legs arranged in three clusters of three connection points each. This isn't arbitrary—it's the result of extensive analysis to optimize:

Load distribution across the platform

Kinematic stability throughout the motion envelope

Mechanical stress patterns under dynamic loading

Manufacturing precision and assembly consistency

Every connection point uses ball joints to provide the rotational freedom necessary for complex 6-DOF motion while maintaining the structural integrity needed for high-performance operation.

Strategic Tilting: Maximizing Performance in Minimal Space

One of the PDK's most innovative features is nearly invisible: strategic actuator positioning. Rather than mounting motors and pneumatic elements vertically, we've carefully tilted each component from the vertical axis.

The Engineering Benefits

Maximized Ball Joint Range: Tilted mounting allows each ball joint to utilize its full deflection span, extending the platform's motion envelope without increasing the base footprint.

Enhanced Kinematic Stability: The tilted configuration reduces the likelihood of approaching kinematic singularities—positions where the platform loses degrees of freedom or becomes difficult to control.

Compact Footprint: Strategic tilting enables us to pack professional-grade performance into just one square meter, making the PDK practical for spaces where traditional motion platforms simply won't fit.

Optimized Load Paths: The tilted geometry creates more efficient force transmission paths, reducing stress concentrations and improving system durability.

Passive Intelligence: The Weight Compensation Advantage

The three pneumatic elements represent a breakthrough in motion platform design. By operating passively during motion, they solve the fundamental challenge of direct-drive systems: the massive torque requirements for supporting payload weight.

How It Works

During operation, the pneumatic system continuously monitors the platform's load and automatically adjusts air pressure to counteract gravitational forces. This means the six servomotors can dedicate their full torque capacity to creating motion rather than fighting gravity.

The result? Levitation-like fluidity even with heavy payloads, combined with the lightning-fast response times that only direct-drive systems can deliver.

Engineering Excellence in Every Detail

This architecture isn't just theoretically elegant—it's been proven through extensive real-world testing:

Motion envelope analysis across over 2 billion joint parameter combinations

Stress testing under 3G acceleration loads

Precision verification down to sub-millimeter accuracy

Durability validation through thousands of motion cycles

The Result: Professional Performance, Practical Package

The PDK's revolutionary architecture delivers specifications that seemed impossible just years ago:

1.4ms latency from signal to motion

250kg payload capacity in levitation-like smooth operation

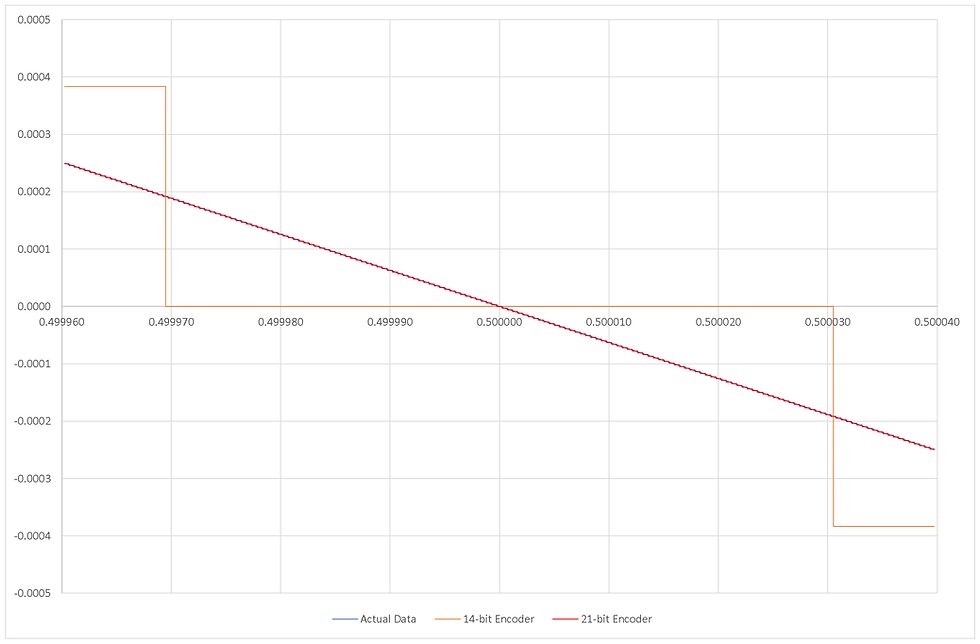

21-bit precision across all six degrees of freedom

30kW peak power in a 1m² footprint

Professional reliability at developer-friendly pricing

Beyond Innovation: Production Reality

This isn't experimental technology—it's production-proven architecture. Every PDK embodies years of architectural refinement, from the mathematical optimization of connection point geometry to the practical engineering of tilted actuator mounting.

The nonapod configuration, strategic tilting, and passive weight compensation work together to create something genuinely new: a motion platform that combines the precision of research-grade equipment with the practicality and affordability that real-world applications demand.

The Future Built on Solid Foundations

The PDK's architecture provides the foundation for the next generation of motion simulation applications. Whether you're developing cutting-edge VR experiences, training the next generation of pilots, or pushing the boundaries of robotics research, you're building on an architectural foundation designed for both today's requirements and tomorrow's possibilities.

This is what happens when proven principles meet innovative engineering: revolutionary capability that just works.

Ready to experience revolutionary motion architecture firsthand? The ARK PDK is available now for developers, researchers, and system integrators worldwide.