Direct Drive Motors: Enhancing Motion Platform Efficiency

- chrish960

- Sep 30, 2025

- 3 min read

When it comes to pushing the limits of immersive technology and robotics, precision and efficiency are non-negotiable. High-precision motors are the unsung heroes behind the scenes, powering motion platforms that deliver jaw-dropping realism and responsiveness. But what makes these motors so special? And how do they transform the way motion platforms perform? Let's dive into the world of motion control and discover how direct drive motors motion platform technology is revolutionizing the game.

Why High-Precision Motors Matter in Motion Platforms

Imagine a motion platform that reacts instantly to your every move, with minimal lag and flawless accuracy. That's the magic of high-precision motors. These motors are engineered to deliver exact positioning, smooth acceleration, and consistent torque. The result? Motion platforms that feel natural, immersive, and incredibly responsive.

High-precision motors excel in applications where every millisecond counts. Whether it's a flight simulator replicating turbulent skies or a robotic arm assembling delicate electronics, the demand for pinpoint accuracy is universal. These motors reduce mechanical backlash and eliminate the need for complex gearboxes, which often introduce delays and wear over time.

Key Benefits of High-Precision Motors:

• Enhanced accuracy for precise control

• Reduced maintenance due to fewer moving parts

• Improved reliability in demanding environments

• Lower noise and vibration for smoother operation

By integrating high-precision motors, motion platforms achieve a level of performance that was once thought impossible. This opens doors to new possibilities in XR development, sim racing direct drive systems, and advanced robotics.

The Role of High-Precision Motors in XR and Simulation

Extended reality (XR) experiences thrive on immersion. The slightest delay or jitter can break the illusion and pull users out of the virtual world. High-precision motors XR simulation systems are the backbone of motion platforms that keep XR experiences seamless and believable.

In sim racing, for example, the difference between a good and great setup often comes down to the quality of the motion system. High-precision motors provide rapid, accurate feedback that mimics real-world forces like acceleration, braking, and cornering. This feedback loop enhances driver performance and enjoyment.

For educators and researchers, these motors enable the creation of realistic training simulators. Pilots, surgeons, and heavy machinery operators can practice in safe, controlled environments that replicate real-world conditions with astonishing fidelity.

Practical Applications:

1. Flight simulators that replicate turbulence and wind shear

2. Medical training platforms for surgical precision

3. Robotic arms with delicate handling capabilities

4. Immersive gaming rigs with real-time motion feedback

The precision and responsiveness of these motors make them indispensable tools for anyone serious about pushing the boundaries of simulation and XR.

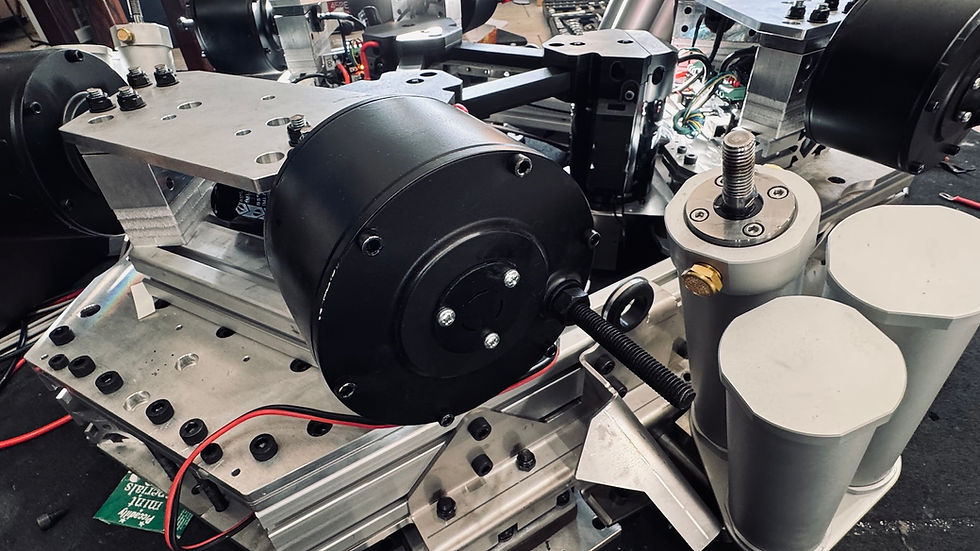

Direct drive motors motion platform

Now, let's talk about the star of the show: direct drive motors. These motors take efficiency and precision to the next level by eliminating intermediary components like gears and belts. The motor shaft connects directly to the load, which means fewer parts to wear out and less energy lost in transmission.

This direct connection translates into several game-changing advantages:

• Instant torque delivery with no lag (1.4ms)

• Minimal mechanical backlash for ultra-precise positioning

• Compact design that saves space and weight

• Lower maintenance costs due to reduced wear and tear

Direct drive motors motion platform integration is particularly well-suited for applications that demand high responsiveness and smooth operation. Their ability to provide consistent torque at low speeds makes them ideal for applications where subtle movements matter.

Why Choose Direct Drive Motors?

• They offer superior control for complex motion profiles

• They reduce system complexity, making integration easier

• They improve overall system reliability and lifespan

For developers and integrators aiming to build next-generation motion platforms, sim racing direct drive motors are a smart investment that pays off in performance and durability.

Can Direct Drive Revolutionize Sim Racing?

Harnessing the power of high-precision motors and direct drive motors is your ticket to creating motion platforms that don't just move - they perform with unmatched accuracy and fluidity. Whether you're building a cutting-edge XR simulator, a professional-grade robotic system, or an educational training rig, these motors provide the foundation for excellence.

Step into the future of motion control with motion platform technology that delivers unmatched results. Explore the possibilities, experiment boldly, and watch your creations come alive with precision and power. The revolution in immersive technology is here - and it's driven by motors that never miss a beat.

Ready to upgrade your rig? Explore our Direct Drive Development Kits or join our community to discuss the future of motion platform technology.